"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

05/21/2018 at 19:32 • Filed to: None

0

0

9

9

"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

05/21/2018 at 19:32 • Filed to: None |  0 0

|  9 9 |

I need advice on whether or not a material I am thinking of using would be appropriate for the job. I need to make some pins for a Powerlifting combo rack. I am thinking about using ETD 150. Would that material be sufficient for the job?

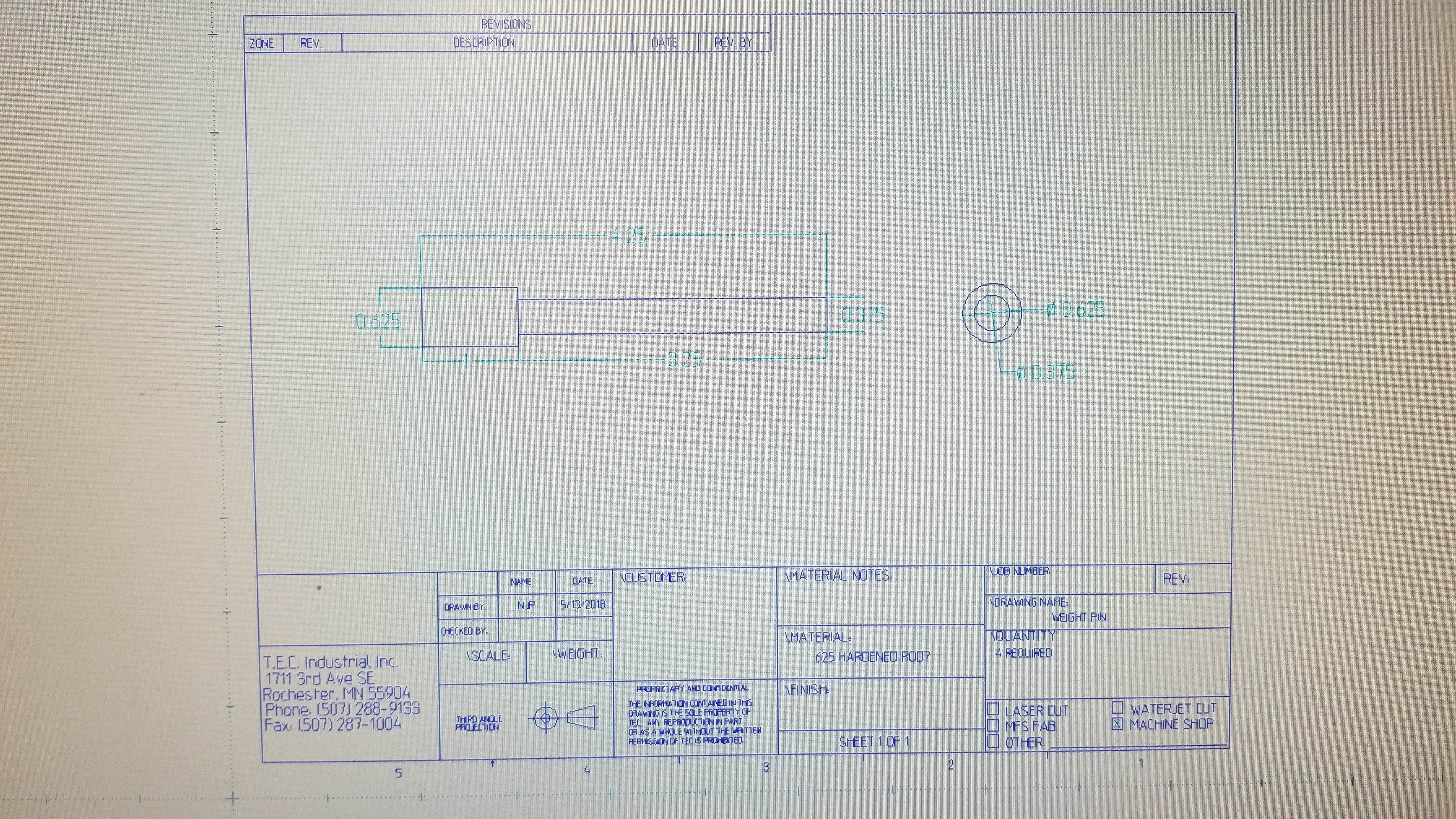

This is the part

This is the material I am thinking of using: https !!!error: Indecipherable SUB-paragraph formatting!!!

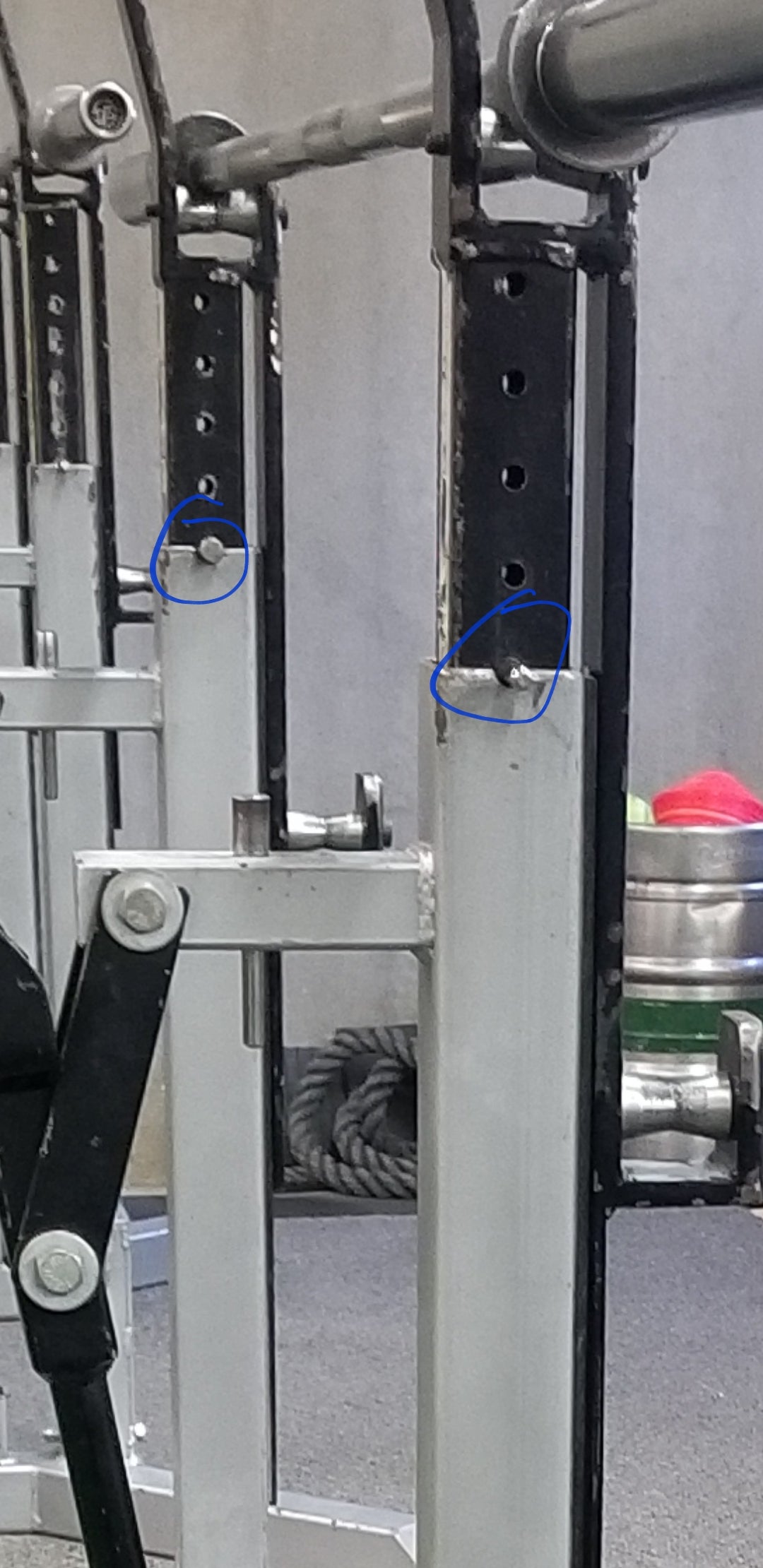

This is where the part is on the rack,

This is the rack itself,

The main gray tube is 2.5x2.5 .125 wall mild steel and the adjustable black tube is 2x2 .125 wall mild steel.

Thank you for any help. I really appreciate it.

Levitas

> Duck Duck Grey Duck FTMFW!

Levitas

> Duck Duck Grey Duck FTMFW!

05/21/2018 at 20:30 |

|

I’m not a certified PE (just a regular BS/MS in aerospace), but my back of the hand calculations say yes, that pin should be safe for that rack, even when loaded past 1000lbs.

DasWauto

> Duck Duck Grey Duck FTMFW!

DasWauto

> Duck Duck Grey Duck FTMFW!

05/21/2018 at 20:31 |

|

For that purpose, unless you are adjusting it dozens of times/day for several years, a piece of 3/8” mild steel rod with a piece of 5/8” .125 wall mild steel tube slipped over and welded onto the end will almost certainly be more than sufficient. I wouldn’t buy pieces of better steel just to turn them down on a lathe for this.

Put a chamfer on the skinny end of the mild steel construction as described above with a grinder and call it good for <$5 in material.

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

05/21/2018 at 20:39 |

|

O’Neal Steel, represent!

They’re one of my few hometown steel companies (or any American steel company, for that matter) to survive all the downturns and outsourcing over the years. One of my old coworkers is the worldwide logistics manager there. Most people around town wouldn’t even know the name.

Bandit

> Duck Duck Grey Duck FTMFW!

Bandit

> Duck Duck Grey Duck FTMFW!

05/21/2018 at 20:43 |

|

Simple rough calculations in my head say you’re fine.... but I haven’t done it since class sophomore year of college. Why not use solid rod instead of tube? Every weights rack I’ve ever used has used solid rod for the added strength.

Here’s a shear calculator:

https://www.engineersedge.com/material_science/bolt_double_shear_calcs.htm

And a rough materials sheet for rod stock

https://www.onealsteel.com/alloy-steel-bar-cd-etd-150.html

DasWauto

> DasWauto

DasWauto

> DasWauto

05/21/2018 at 20:58 |

|

Just checked quickly - even with mild steel pins, your mild steel square tubes will deform under excess load first, and that would take >5000kg.

Duck Duck Grey Duck FTMFW!

> DasWauto

Duck Duck Grey Duck FTMFW!

> DasWauto

05/21/2018 at 23:59 |

|

If they end up being used for competition, the pins would see heavy use on competition days but that may be only once a month. The stands in the picture are actually located at a gym where they get used daily for squats. Would that justify making it out of stronger than mild (1018) steel?

DasWauto

> Duck Duck Grey Duck FTMFW!

DasWauto

> Duck Duck Grey Duck FTMFW!

05/22/2018 at 07:58 |

|

In my opinion, no. The only reason I mentioned the frequency of use in the first comment is a wear concern but having done the quick calculation that I did, the tubes will give before the pins regardless of which material you use so I wouldn’t bother using anything better than mild steel on said pins.

Future ND Owner

> Duck Duck Grey Duck FTMFW!

Future ND Owner

> Duck Duck Grey Duck FTMFW!

05/22/2018 at 13:28 |

|

Use the largest diameter (3/8"?) grade 8 bolt that will fit in the holes. Cheaper and faster than custom fabrication. Plenty strong for that use.

A grade 8 bolt is stronger than the more commonly used grade 5. It is made of alloy steel and has six radial lines on the top of the bolt head. Grade 8 bolts have a tensile strength of 150,000 pounds per square inch.

Duck Duck Grey Duck FTMFW!

> Future ND Owner

Duck Duck Grey Duck FTMFW!

> Future ND Owner

05/22/2018 at 13:42 |

|

The pin is shaped the way it is because when this rack is used during competition, they use those black handles on the back to lift up the loaded barbell to adjust for each lifters height. Thanks for the suggestion though